In modern power distribution systems, Insulation Piercing Connectors (IPC) are game-changers, offering fast, secure, and maintenance-free connections for insulated cables. Designed to penetrate cable insulation without stripping, IPC connector ensure reliable electrical performance in harsh environments. Here’s how they work and their advantages.

What Are Insulation Piercing Connectors?

IPCs are specialized devices that create electrical joints by piercing the insulation of live cables. They eliminate the need for cutting or stripping wires, making them ideal for low-voltage (LV) overhead lines, street lighting, and building electrical systems.

Structure & Materials

Body:

High-strength, UV-resistant polyamide PA 6.6 reinforced with 30-50% glass fibers.

Withstands temperatures from -40°C to +125°C and resists aging.

Contact Plates:

Tin-plated copper or aluminum alloy for excellent conductivity.

Sharp teeth penetrate insulation and grip conductors securely.

Fasteners:

Galvanized steel shear nuts with pre-set torque limits to prevent over-tightening.

Seals:

Elastomer inserts block moisture and prevent bimetallic corrosion.

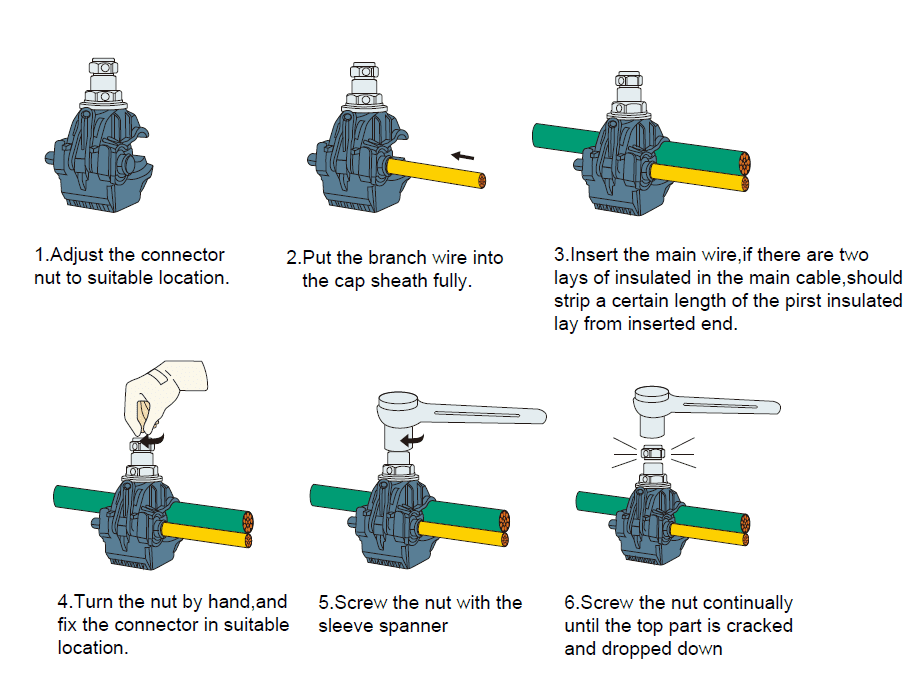

How Do IPC connector Work?

Installation:

Place the IPC connector over the main and tap cables.

Tighten the shear nut until the head breaks off, ensuring optimal contact pressure.

Contact plates pierce insulation, creating a gas-tight connection.

Key Features:

Live Installation: Safe for energized lines with proper PPE.

Dual-Metal Compatibility: Connects aluminum-to-aluminum or aluminum-to-copper cables.

5 Advantages of the IPC connector

Weatherproof & Durable:

IP68 rating (6kV underwater tested) resists rain, ice, and humidity.

Corrosion Resistance:

Elastomer seals and contact grease prevent oxidation.

Time & Cost Savings:

No stripping or tools are required; installation is in minutes.

Theft Prevention:

Tamper-proof design deters cable theft.

Versatility:

Fits conductors from 1.5 mm² to 240 mm² (aluminum or copper).

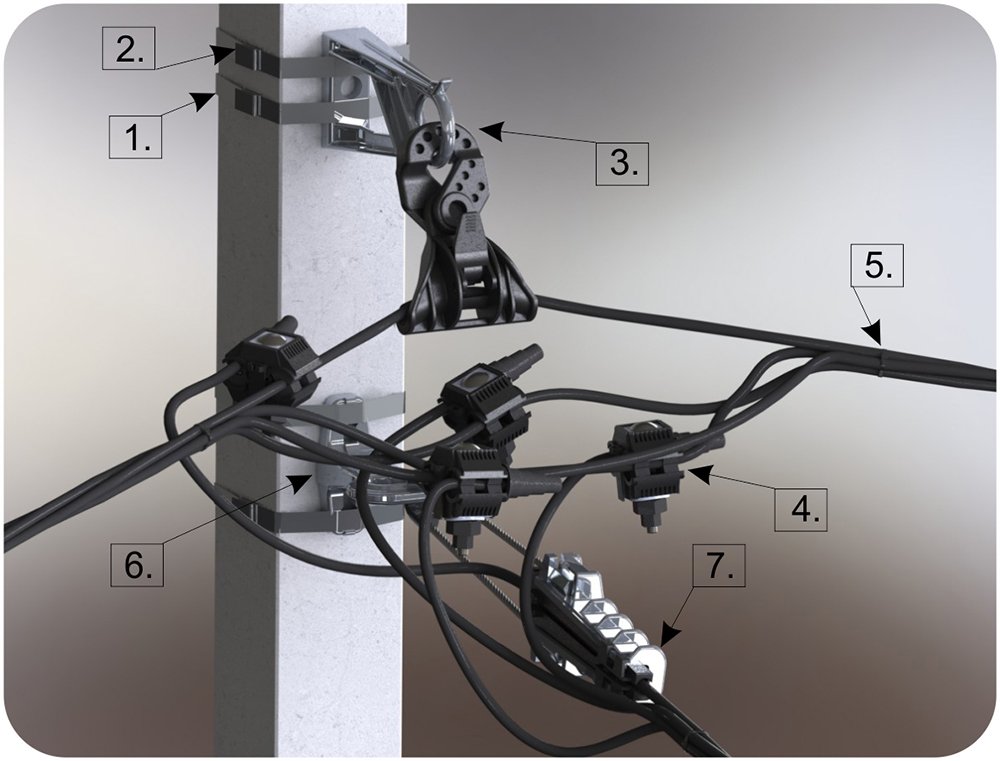

Applications

Street Lighting: Splice LV ABC cables without downtime.

Building Electrical Systems: Connect risers in high-rise electrical shafts.

Renewable Energy: Link solar PV arrays to grid lines.

Railways: Waterproof joints for outdoor traction power systems.

Why Choose WZUMER IPC Connectors?

Certified Quality:

Complies with CE, UL, IP, REACH, and RoHS standards.

Safety First:

Pre-lubricated end caps and shear nuts ensure consistent torque.

Global Support:

24/7 technical guidance for installations or custom designs.

Inventory Efficiency:

Universal designs reduce SKU complexity.

Explore WZUMER’s Range:

Standard IPCs: For 1.5–240 mm² cables.

Hybrid Kits: Include grease-filled caps and mounting tools.

Need Reliable Cable Joints?

�� Contact WZUMER for free samples or download installation guides today!