Insulation Piercing Connectors are mainly composed of an insulating shell, a piercing blade, a waterproof rubber pad, and a torque bolt. When making a piercing clamp (1 piece) for cable branch connection, insert the branch cable into the branch cap and determine the branch position of the main line. Use a socket wrench to tighten the torque nut on the clamp. As the torque nut is tightened, the clamp moves up and down. The insulator with the hidden piercing blade gradually closed. At the same time, the arc-shaped sealing rubber pad wrapped around the piercing blade gradually adhered to the cable insulation layer, and the piercing blade began to pierce the cable insulation layer and the metal conductor. When the sealing degree of the sealing rubber gasket and the insulating grease, and the contact between the piercing blade and the metal body, reach the best effect, the torque nut will automatically fall off. At this time, the installation is completed, and the contact point sealing and electrical effects are optimal.

1. Overview of the insulation piercing connector

1.1 Piercing structure, simple installation, no need to strip insulated wires;

1.2 Torque nut, the puncture pressure is constant, to ensure a good electrical connection without damaging the wire.

1.3 Self-sealing structure, moisture-proof, waterproof, anti-corrosion, extending the service life of insulated wires and clamps

1.4 Using special contact blades, suitable for copper (aluminum) butt joint and copper-aluminum transition

1.5 The electrical contact resistance is small, and the contact resistance is less than 1.1 times the resistance of the equal-length branch wire, which meets the DL/T765.1-2001 standard

1.6 Special insulating shell, anti-light and environmental aging, dielectric strength> 12 kV

1.7 arc design, suitable for the same (different) diameter wire connection, wide connection range (0.75mm2-400mm2)

2. Performance experiment of the insulation piercing connector

2.1 Mechanical properties: The gripping force of the clamp is greater than 1/10 of the wire breaking force, which meets the requirements of GB2314-1997

2.2 Temperature rise performance: In the case of high current, the temperature rise of the clamp is connected to the temperature rise of the wire

2.3 Thermal cycle performance: Meet the GB/T2317-2000 thermal cycle test standard for electric power fittings.

2.4 Waterproof insulation performance: meet the relevant test requirements of GB/T13140-1998 Part 2

2.5 Anti-corrosion performance: Do three 14-day cycle tests in sulfur dioxide and salt spray environment.

2.6 Environmental aging performance: six weeks of exposure to UV, dry, and humid environments, temperature changes, and thermal shocks

2.7 Fire performance: The insulating material of the connecting device withstands the glow-wire test and meets the requirements of Chapter 4-10 of GB/T5169.4

3. Insulation Piercing Connector Advantages

Easy to install

The cable branch can be made without stripping the insulation of the cable, and the connector is completely insulated. No need to cut off the main cable, can branch at any position of the cable. The installation is simple and reliable, and it can be installed with electricity only by using a socket wrench.

Safe use

The joint is resistant to distortion, shockproof, waterproof, flame-retardant, anti-electrochemical corrosion, and aging, and requires no maintenance. It has been used successfully for more than 30 years.

Cost saving

The installation space is extremely small, saving bridge and civil construction costs. Application in construction, no terminal box or branch box is needed.

There is no need for a cable return, which saves cable investment. The cost of cable + piercing clamp is lower than other power supply systems, and only plug-in

About 40% of the busbar is made up of 60% the prefabricated branch cable.

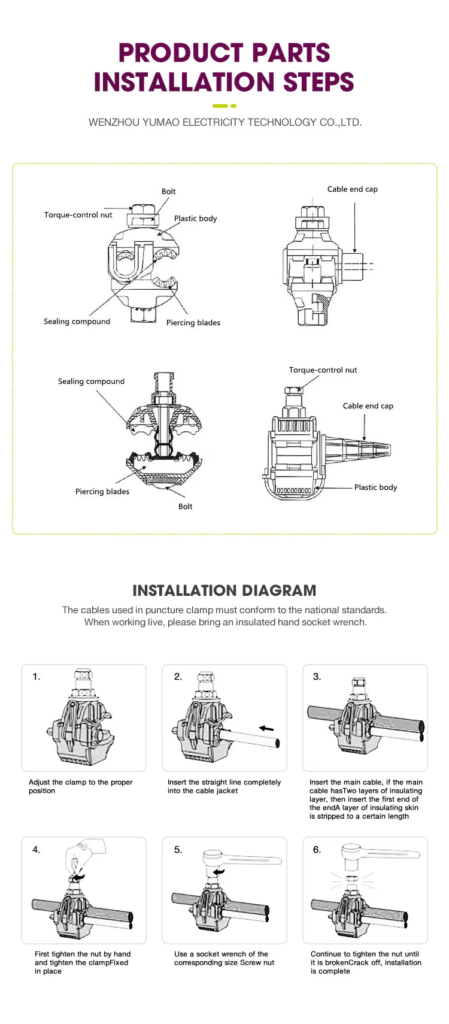

IPC Connector Installation Method

1. Adjust the puncture clamp nut to a suitable position, and insert the branch line into the branch line cap cover.

2. Insert the main line. If the main line has two layers of insulation, a certain length of outer insulation should be stripped at the connection position.

3. Put the main and branch lines in the proper position and keep them parallel. First, tighten the nut by hand to fix the clamp.

4. Tighten the nuts evenly with a sleeve wrench of the corresponding size until the top breaks off and the installation is complete.

Insulation piercing connector category

Insulation piercing clamps can be divided into 1 kV, 10 kV, and 20 kV insulation piercing clamps according to voltage classification.

According to the function classification, it can be divided into ordinary insulation piercing clamps, electrical grounding insulation piercing clamps, lightning protection, and arc insulation piercing clamps!