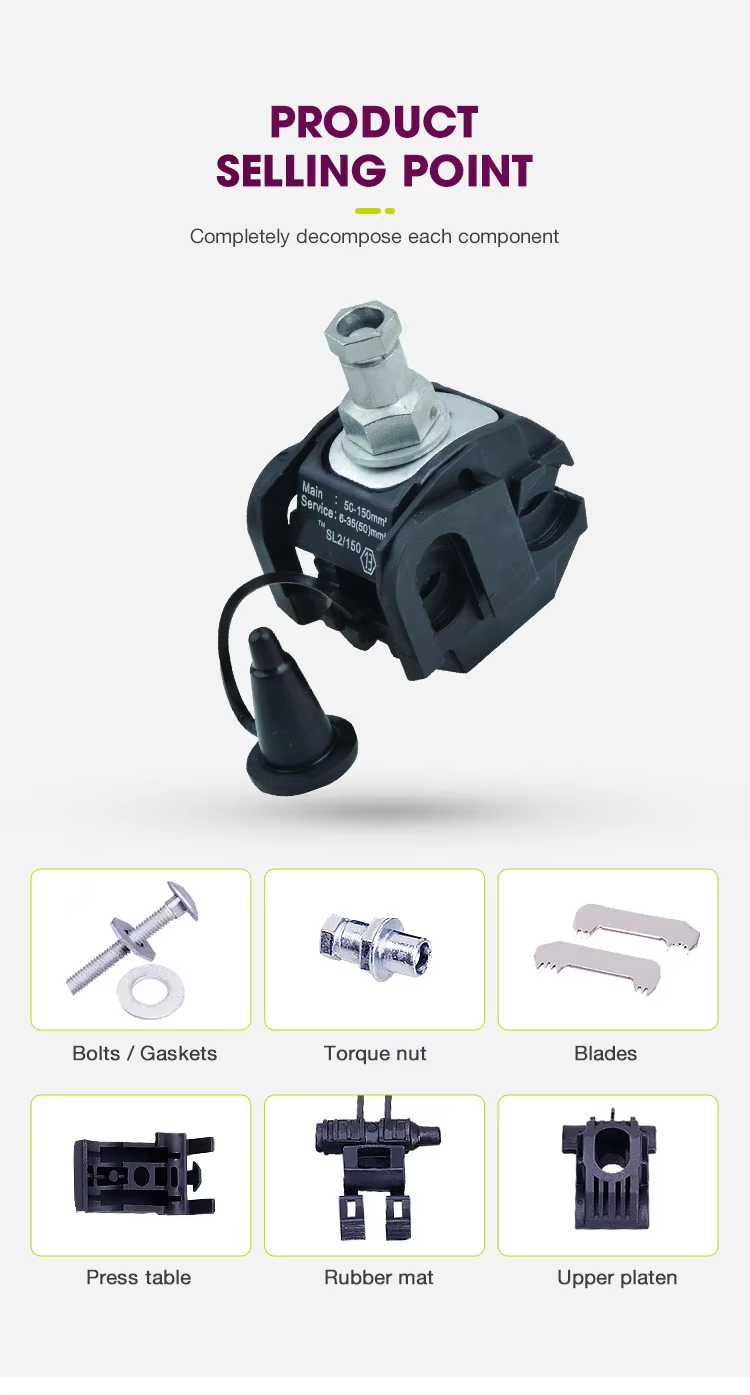

Voltage Aerial Bundle Cable SL2-150 Insulation Piercing Connector

The SL2-150 Insulation Piercing Connector supports 50-150mm² main cables and 6-50mm² branches with a 157A current rating. Compact (46×52×87mm, 162g) and robust, its 2.5-3.5mm piercing depth ensures secure, tool-free connections using a single bolt. Ideal for high-current applications like power distribution grids and streetlight systems.

Additional information

Product Description:

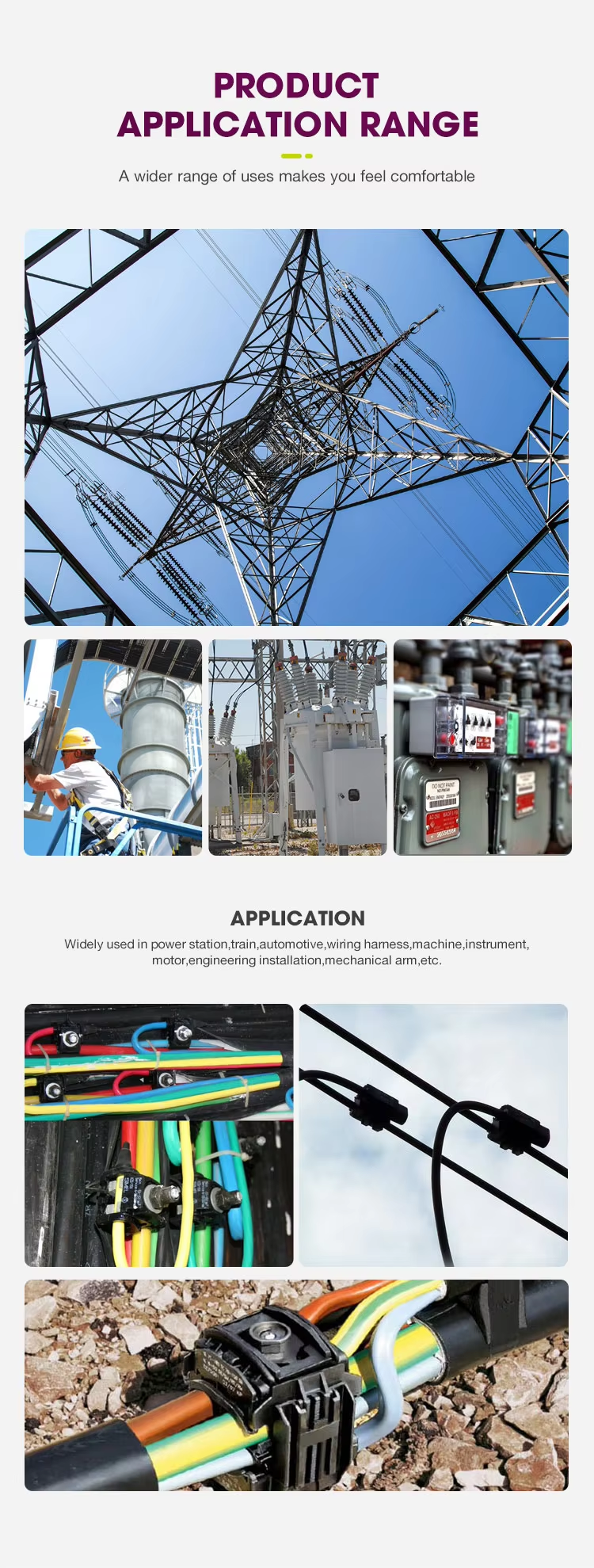

Used for branch connection of insulated cable for building distribution system, connection of LV overhead insulated cables, branch connection of LV insulated service-entrance cable, distribution system of streetlight

etc.

Main line: insulated copper or aluminum

Branch wire: insulated copper or aluminum

Live-line work or power-cut work is allowable

The main body of the connector is made of high-strength insulating material that is resistant to mechanical change or climatic variation.

The connector features a property, it can withstand a voltage of 6kV in water without a breakdown phenomenon.

*The waterproof sealing end cap of the branch line prevents water from entering the branch connected conductor; it can be branched on the left or right side according to demand.

| Dimensions | |

| Main Cable Line | 50-150mm² |

| Branch Cable Line | 6-35(50)mm² |

| Norminal Current | 157A |

| Dimensions | 46x52x87 |

| Piercing Depth | 2.5-3.5mm |

| Weight | 162g |

| Bolts | 1 PCS |

Performance Test:

Mechanical performance: The clamping force of the wire clamp is greater than 1/10 of the breaking force of the steel wire, in line with GB2314-1997 standard.

Temperature rise performance: keep the temperature rise of the connecting wire under high current conditions.

Thermal cycling performance: in line with GB/T2317-2000 power fixture thermal cycling test standards.

Waterproof insulation performance: in line with GB/T13140-1998 part 2 standard.

Corrosion resistance: Successfully passed three 14-day cycle tests under sulfur dioxide and salt spray environments.

Environmental aging performance: Exposed to ultraviolet rays, dry and humid environments, temperature changes, and thermal shock for six weeks.

Fire resistance: Insulation material meets the requirements of GB/T5169.4, chapter 4-10 after the burning wire test.